In production of lift truck, Toyota places the highest value on safety in operation of lift trucks. The System of Active Stability (SAS) based on innovative technologies is able to reduce the risk of accidents. This system is added with the intelligent Operator Presence Sensing System (OPS) which ensures operational safety of operators.

System of Active Stability (SAS)

The System of Active Stability (SAS) was specially designed for Toyota forklifts for the purpose of prevention of any accidents and injuries. This system is able to electronically monitor and control more than 3000 key functions of a forklift. The SAS was developed on the basis of an electronic controller, 10 sensors and 3 actuating mechanisms. The SAS controller will calculate from the information of the sensors whether the forklift is in a potentially dangerous situation or not, and will accordingly activate the appropriate actuator(s).

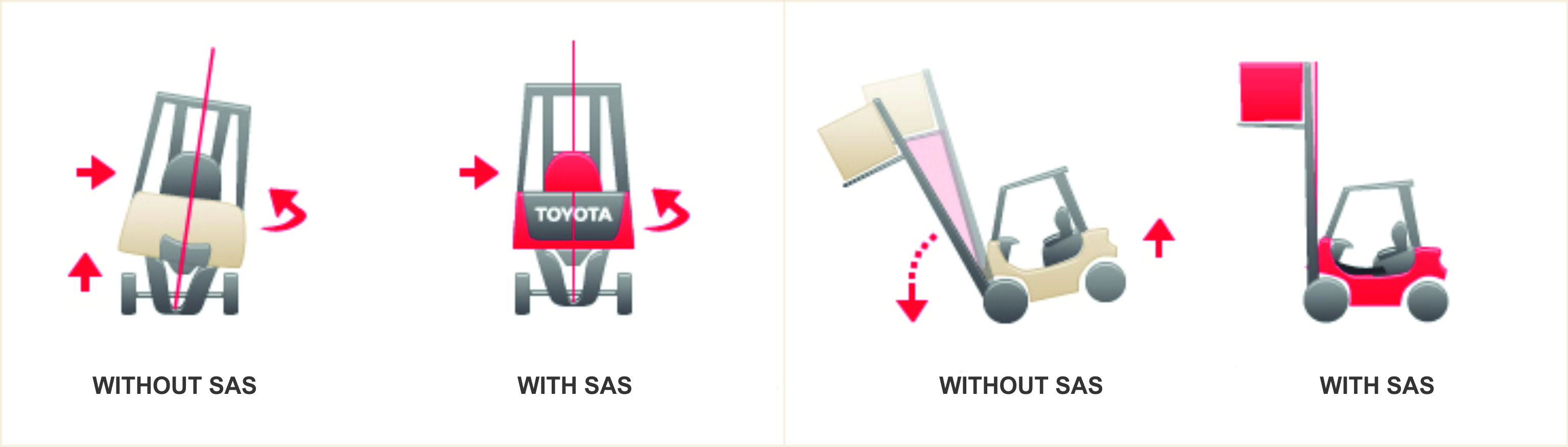

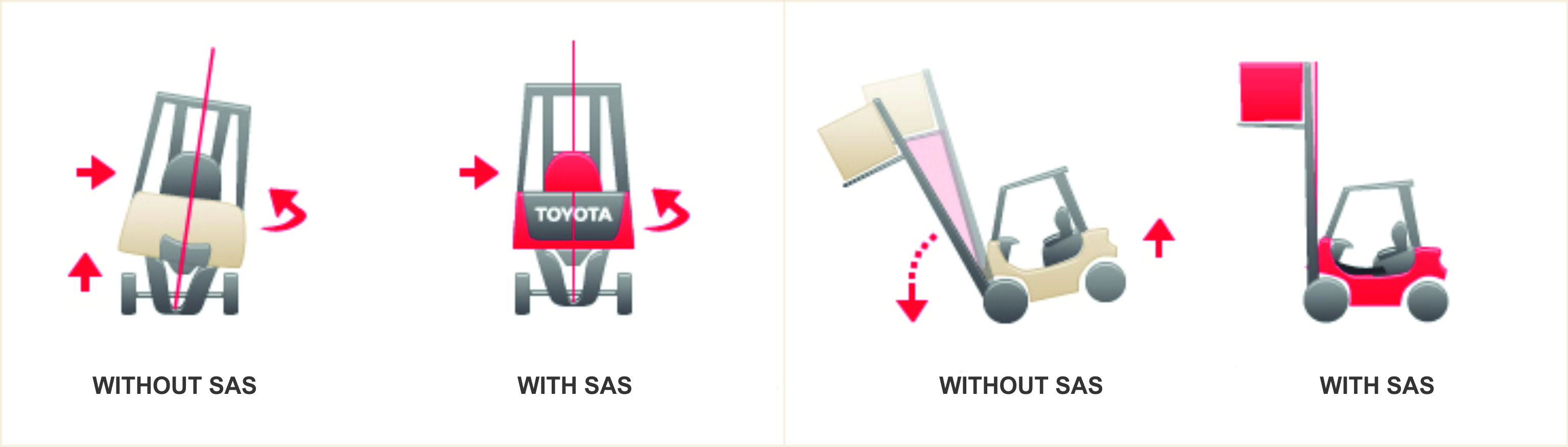

Prevention from Forklift Lateral Instability

A side tip-over happens when the position of the centre of gravity of the forklift moves sideways, out of the stability area of the forklift. Typically, this happens, when a forklift is turning at high speeds, or changing directions. As a rule, the rear axle is free to pivot, to cope with the uneven floor conditions. To prevent this Toyota has developed a steer axle locking device. It temporarily locks the steer axle, transforming the triangle of stability into a rectangle to ensure high transversal stability of the forklift.

The System of Active Stability ensures extraordinary stability, which is a key factor of safety!

Operator Presence Sensing System (OPS)

The Operator Presence Sensing System (OPS) helps to prevent accidental movement of the forklift and forks when the opertaror is not seated at the controls. This system was created once again by Toyota with the purpose to ensure high level of safety for an operator and other people within the forklift operating area. The OPS system senses if the operator is properly seated at the controls by means of the seat switch. When the operator is properly seated at the controls the seat switch will go "on". If the operator is not seated at the controls the seat switch will turn "off", and the OPS system will disable the ability to lower the forks, or tilt forward or back along with all the other loading and unloading movements. In order to turn off the OPS system, the operator has to return to his seat, to turn on the seat switch and to set the forward/reverse and control levers to neutral position for further movement and lowering of forks.